- Abracon

- Adam Tech

- Aerospace, Defense & Marine

- Agastat

- AIC

- AKM Semiconductor

- Alcoswitch

- Allegro

- Alps Electric

- Altera

- AMI Semiconductor

- AMP

- ams

- Analog Devices (ADI)

- Aptina Imaging

- Atmel

- Avago / Broadcom

- AVX

- Axicom

- Bccomponents

- Beyschlag

- BI Technologies

- Bourns Inc.

- Bowei Integrated Circuits

- Bridgelux

- Buchanan

- California Micro Devices

- Catalyst Semiconductor

- CGS

- Cirrus Logic

- Citizen Electronics

- CML Microcircuits

- Coiltronics

- Cooper Bussmann

- Corcom

- Core Logic

- Cree

- CSR PLC

- CTS

- Cypress Semiconductor

- Dale

- Data Image

- Deutsch

- Diodes Incorporated

- DOMINANT Opto Technologies

- E-T-A

- Eaton

- ECS

- Edison Opto

- Elcon

- EPCOS

- Epistar

- Epson

- Everlight Electronics

- Exar

- Fairchild Semiconductor

- FCI

- Freescale Semiconductor

- Fremont Micro Devices (FMD)

- Fujitsu Semiconductor

- Fulltech Electric

- General Semiconductor

- Harvatek

- Holsworthy

- Hsuan Mao Technology

- IDT

- Infineon Technologies

- Innolux

- International Rectifier (IR)

- Intersil

- IRC

- ISSI

- IXYS-IC

- Jing Cheng Electronical

- JL World

- Johanson Dielectrics

- Johanson Technology

- JRC / NJR

- JST

- KEC

- Kilovac

- Kingbright

- Kyocera Industrial Ceramics

- LEDiL

- Linear Technology / ADI

- Lite-On Technology

- Littelfuse

- Lumex

- Lumileds

- Luminary Micro

- Luminus Devices

- Macronix

- Maojwei / ZJPT

- Maxim Integrated

- MCC

- Mean Well Enterprises

- Microchip Technology

- Micron

- Microsemi

- Mini-Circuits

- Molex

- Murata Manufacturing

- Murata Power Solutions

- MWT

- National Semiconductor

- Nichicon

- Nippon Chemi-Con

- NJR / JRC

- NVE

- NXP Semiconductors

- OEG

- Omnivision

- ON Semiconductor

- Optek Technology

- Optrex

- OSRAM Opto Semiconductors

- OTAX

- Panasonic

- Peregrine(pSemi)

- Potter & Brumfield

- Power Integrations

- PowerStor

- Preci-Dip

- Prewell

- Products Unlimited

- Pulse Electronics

- PulseCore Semiconductor

- Qorvo

- Raychem

- Renesas Electronics

- RFMD

- Richtek Technology

- ROHM Semiconductor

- Rubycon

- Samsung Electro-Mechanics

- Samsung Semiconductor

- Schaffner

- Schrack

- Seiko Instruments, Inc. (SII)

- Semtech

- Sensata

- Seoul Semiconductor

- Sfernice

- Sharp Display

- Sharp Microelectronics

- Silicon Labs

- Siliconix

- Skyworks Solutions

- SoniCrest / JL World

- Spansion

- Sprague

- Stanley Electric

- STMicroelectronics

- Sunny Electronics

- Susumu (SSM)

- Taimag

- Taiyo Yuden

- TDK

- TDK-Lambda

- TE Connectivity

- Teccor

- Texas Instruments (TI)

- Thin Film

- Tianma Micro-electronics

- TOCOS

- TOKO

- Toshiba Electronic Components

- TT Electronics

- Tusonix

- TXC

- Tyntek

- Vishay

- Vishay Precision Group

- Vitramon

- Walsin Technology

- Weidmuller

- Welwyn

- Wickmann

- Winbond

- Xilinx

- Yageo

- Zetex Semiconductors

- ZJPT / Maojwei

News

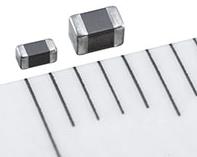

EMC components and inductors : First chip beads and inductors with robust soft termination

2017-03-21 | Return TDK Corporation presents the world’s first multilayer chip beads and inductors with the innovative soft-termination technology that is already proven in TDK MLCCs. The external electrodes of the new KMZ1608 and KPZ1608 series of chip beads and the KLZ1608 and KLZ2012 series of inductors feature a conductive resin layer that offers effective protection against board flexure and solder cracks due to mechanical stress during mounting and thermal shock during operation. As a result, these soft-termination automotive-grade components offer high reliability under harsh conditions, even at high operating temperatures up to 150 °C. They are thus suitable for demanding automotive applications, such as engine control modules (ECMs) and various in-vehicle electronic control units (ECUs), and advanced driver assistance systems (ADAS), as well as in a variety of industrial equipment.

TDK Corporation presents the world’s first multilayer chip beads and inductors with the innovative soft-termination technology that is already proven in TDK MLCCs. The external electrodes of the new KMZ1608 and KPZ1608 series of chip beads and the KLZ1608 and KLZ2012 series of inductors feature a conductive resin layer that offers effective protection against board flexure and solder cracks due to mechanical stress during mounting and thermal shock during operation. As a result, these soft-termination automotive-grade components offer high reliability under harsh conditions, even at high operating temperatures up to 150 °C. They are thus suitable for demanding automotive applications, such as engine control modules (ECMs) and various in-vehicle electronic control units (ECUs), and advanced driver assistance systems (ADAS), as well as in a variety of industrial equipment.

The demand for compact, lightweight and robust multilayer inductive components is steadily growing as the electronic functionality of vehicles continues to increase and as more and more ECUs are positioned closer to the engine. The new KMZ1608 and KPZ1608 series of chip beads are available in IEC 1608 case size with dimensions of 1.6 mm x 0.8 mm x 0.8 mm. The KLZ1608 and KLZ2012 series are available in IEC 1608 and 2012 case sizes and measure in at 1.6 mm x 0.8 mm x 0.8 mm and 2.0 mm x 1.25 mm x 1.25 mm, respectively. The lineup of multilayer chip beads and inductors with soft terminations will be continuously expanded to include smaller case sizes. Volume production of the AEC-Q200 qualified products began in March 2017.

Glossary

Soft termination: The terminal electrode of standard products consists of three layers: copper (Cu), nickel (Ni), and tin (Sn) on the base electrode of Ag. The terminal electrode of soft-termination components consists of two layers: Ni and Sn bonded to the Ag base electrode with an elastic resin.

Main applications

。Engine control modules (ECM) and various in-vehicle electronic control units (ECU)

。Advanced driver assistance systems (ADAS)

。Industrial equipment

Main features and benefits

。Effective protection against board flexure and solder cracks

。Suitable for high operating temperatures up to 150 °C

Key data

Chip beads

Series |

Impedance [Ω] |

DC resistance |

Rated current [mA] max. |

||

-55 to +125 °C |

+125 to +150 °C |

||||

KMZ1608 |

50 to 2500 |

0.1 to 0.8 |

200 to 800 |

100 to 400 |

|

-55 to +85 °C |

+125 °C |

+150 °C |

|||

KPZ1608 |

30 to 1000 |

0.015 to 0.3 |

800 to 5000 |

500 to 2000 |

300 to 1000 |

Inductors

Series |

Inductance |

DC resistance |

Rated current [mA] max. |

KLZ1608 |

1.0 to 22 |

0.15 to 2.4 |

55 to 190 |

KLZ2012 |

1.0 to 100 |

0.10 to 3.7 |

30 to 700 |

Source:http://www.global.tdk.com/