Manufacturers

- Abracon

- Adam Tech

- Aerospace, Defense & Marine

- Agastat

- AIC

- AKM Semiconductor

- Alcoswitch

- Allegro

- Alps Electric

- Altera

- AMI Semiconductor

- AMP

- ams

- Analog Devices (ADI)

- Aptina Imaging

- Atmel

- Avago / Broadcom

- AVX

- Axicom

- Bccomponents

- Beyschlag

- BI Technologies

- Bourns Inc.

- Bowei Integrated Circuits

- Bridgelux

- Buchanan

- California Micro Devices

- Catalyst Semiconductor

- CGS

- Cirrus Logic

- Citizen Electronics

- CML Microcircuits

- Coiltronics

- Cooper Bussmann

- Corcom

- Core Logic

- Cree

- CSR PLC

- CTS

- Cypress Semiconductor

- Dale

- Data Image

- Deutsch

- Diodes Incorporated

- DOMINANT Opto Technologies

- E-T-A

- Eaton

- ECS

- Edison Opto

- Elcon

- EPCOS

- Epistar

- Epson

- Everlight Electronics

- Exar

- Fairchild Semiconductor

- FCI

- Freescale Semiconductor

- Fremont Micro Devices (FMD)

- Fujitsu Semiconductor

- Fulltech Electric

- General Semiconductor

- Harvatek

- Holsworthy

- Hsuan Mao Technology

- IDT

- Infineon Technologies

- Innolux

- International Rectifier (IR)

- Intersil

- IRC

- ISSI

- IXYS-IC

- Jing Cheng Electronical

- JL World

- Johanson Dielectrics

- Johanson Technology

- JRC / NJR

- JST

- KEC

- Kilovac

- Kingbright

- Kyocera Industrial Ceramics

- LEDiL

- Linear Technology / ADI

- Lite-On Technology

- Littelfuse

- Lumex

- Lumileds

- Luminary Micro

- Luminus Devices

- Macronix

- Maojwei / ZJPT

- Maxim Integrated

- MCC

- Mean Well Enterprises

- Microchip Technology

- Micron

- Microsemi

- Mini-Circuits

- Molex

- Murata Manufacturing

- Murata Power Solutions

- MWT

- National Semiconductor

- Nichicon

- Nippon Chemi-Con

- NJR / JRC

- NVE

- NXP Semiconductors

- OEG

- Omnivision

- ON Semiconductor

- Optek Technology

- Optrex

- OSRAM Opto Semiconductors

- OTAX

- Panasonic

- Peregrine(pSemi)

- Potter & Brumfield

- Power Integrations

- PowerStor

- Preci-Dip

- Prewell

- Products Unlimited

- Pulse Electronics

- PulseCore Semiconductor

- Qorvo

- Raychem

- Renesas Electronics

- RFMD

- Richtek Technology

- ROHM Semiconductor

- Rubycon

- Samsung Electro-Mechanics

- Samsung Semiconductor

- Schaffner

- Schrack

- Seiko Instruments, Inc. (SII)

- Semtech

- Sensata

- Seoul Semiconductor

- Sfernice

- Sharp Display

- Sharp Microelectronics

- Silicon Labs

- Siliconix

- Skyworks Solutions

- SoniCrest / JL World

- Spansion

- Sprague

- Stanley Electric

- STMicroelectronics

- Sunny Electronics

- Susumu (SSM)

- Taimag

- Taiyo Yuden

- TDK

- TDK-Lambda

- TE Connectivity

- Teccor

- Texas Instruments (TI)

- Thin Film

- Tianma Micro-electronics

- TOCOS

- TOKO

- Toshiba Electronic Components

- TT Electronics

- Tusonix

- TXC

- Tyntek

- Vishay

- Vishay Precision Group

- Vitramon

- Walsin Technology

- Weidmuller

- Welwyn

- Wickmann

- Winbond

- Xilinx

- Yageo

- Zetex Semiconductors

- ZJPT / Maojwei

News

Revolutionary LCT Redefines Power Supply Noise Suppression, Cutting Costs and Component Count

2024-05-14 | Return

As the demand for miniaturized and highly functional electronics increases, the issue of electromagnetic noise is becoming increasingly prominent for many industries. As a noise countermeasure, capacitors are often utilized between the power supply line and ground, but this method is not without its challenges. The noise removal effectiveness of the capacitor is optimal when a capacitor’s impedance is lowest. However, capacitor impedance can rise due to its ESL, particularly at frequencies beyond the self-resonant frequency, undermining the efficacy of the noise cancellation. To minimize this impact, it is common practice to connect numerous capacitors in parallel in order to collectively reduce impedance, at the expense of Bill of Material (BoM) component count and costs.

Murata’s LCT is a revolutionary new concept capable of resolving the longstanding challenge of managing power supply noise and capacitor component count. Murata’s LCT component is specifically engineered to minimize noise within the frequency range of a few MHz to 1GHz. It achieves this by utilizing negative mutual inductance to reduce a noise-reducing capacitor’s ESL and therefore increase the effectiveness of its operation, drastically reducing the number of required capacitors.

By using non-magnetic ceramic multilayer technology in its construction, the LCT ensures stable negative inductance and low DC resistance (maximum 55mΩ) even in the presence of current variations and is suitable for a wide range of applications, including consumer, industrial and healthcare products. Murata’s LCT breakthrough is a result of their extensive multilayer ceramic knowledge and redefines power supply noise reduction circuit design, and minimizes a significant and persistent electronic design challenge.

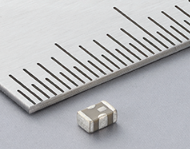

Each LCT is suitable for temperatures up to temperatures 125oC and since there is no DC superposition characteristic, it can be used with stable negative inductance up to 3A. The surface mount device (SMD) measures just 2.0 x 1.25 x 0.95 mm and is available in tape and reel packing.

“Murata’s new LCT is a true innovation that does not merely improve what is available, but redefines what is seen as a standard noise suppression component by radically redefining the entire concept”, said Masamichi Ando, Vice President Business Incubation Center Corporate Technology & Business Development Unit, at Murata. “With this revolutionary component, engineers will be able to reduce component count, system complexity and costs, helping to both further miniaturize their solutions and reduce its impact on the environment by lowering material consumption.”

Source: http://www.murata.com