Manufacturers

- Abracon

- Adam Tech

- Aerospace, Defense & Marine

- Agastat

- AIC

- AKM Semiconductor

- Alcoswitch

- Allegro

- Alps Electric

- Altera

- AMI Semiconductor

- AMP

- ams

- Analog Devices (ADI)

- Aptina Imaging

- Atmel

- Avago / Broadcom

- AVX

- Axicom

- Bccomponents

- Beyschlag

- BI Technologies

- Bourns Inc.

- Bowei Integrated Circuits

- Bridgelux

- Buchanan

- California Micro Devices

- Catalyst Semiconductor

- CGS

- Cirrus Logic

- Citizen Electronics

- CML Microcircuits

- Coiltronics

- Cooper Bussmann

- Corcom

- Core Logic

- Cree

- CSR PLC

- CTS

- Cypress Semiconductor

- Dale

- Data Image

- Deutsch

- Diodes Incorporated

- DOMINANT Opto Technologies

- E-T-A

- Eaton

- ECS

- Edison Opto

- Elcon

- EPCOS

- Epistar

- Epson

- Everlight Electronics

- Exar

- Fairchild Semiconductor

- FCI

- Freescale Semiconductor

- Fremont Micro Devices (FMD)

- Fujitsu Semiconductor

- Fulltech Electric

- General Semiconductor

- Harvatek

- Holsworthy

- Hsuan Mao Technology

- IDT

- Infineon Technologies

- Innolux

- International Rectifier (IR)

- Intersil

- IRC

- ISSI

- IXYS-IC

- Jing Cheng Electronical

- JL World

- Johanson Dielectrics

- Johanson Technology

- JRC / NJR

- JST

- KEC

- Kilovac

- Kingbright

- Kyocera Industrial Ceramics

- LEDiL

- Linear Technology / ADI

- Lite-On Technology

- Littelfuse

- Lumex

- Lumileds

- Luminary Micro

- Luminus Devices

- Macronix

- Maojwei / ZJPT

- Maxim Integrated

- MCC

- Mean Well Enterprises

- Microchip Technology

- Micron

- Microsemi

- Mini-Circuits

- Molex

- Murata Manufacturing

- Murata Power Solutions

- MWT

- National Semiconductor

- Nichicon

- Nippon Chemi-Con

- NJR / JRC

- NVE

- NXP Semiconductors

- OEG

- Omnivision

- ON Semiconductor

- Optek Technology

- Optrex

- OSRAM Opto Semiconductors

- OTAX

- Panasonic

- Peregrine(pSemi)

- Potter & Brumfield

- Power Integrations

- PowerStor

- Preci-Dip

- Prewell

- Products Unlimited

- Pulse Electronics

- PulseCore Semiconductor

- Qorvo

- Raychem

- Renesas Electronics

- RFMD

- Richtek Technology

- ROHM Semiconductor

- Rubycon

- Samsung Electro-Mechanics

- Samsung Semiconductor

- Schaffner

- Schrack

- Seiko Instruments, Inc. (SII)

- Semtech

- Sensata

- Seoul Semiconductor

- Sfernice

- Sharp Display

- Sharp Microelectronics

- Silicon Labs

- Siliconix

- Skyworks Solutions

- SoniCrest / JL World

- Spansion

- Sprague

- Stanley Electric

- STMicroelectronics

- Sunny Electronics

- Susumu (SSM)

- Taimag

- Taiyo Yuden

- TDK

- TDK-Lambda

- TE Connectivity

- Teccor

- Texas Instruments (TI)

- Thin Film

- Tianma Micro-electronics

- TOCOS

- TOKO

- Toshiba Electronic Components

- TT Electronics

- Tusonix

- TXC

- Tyntek

- Vishay

- Vishay Precision Group

- Vitramon

- Walsin Technology

- Weidmuller

- Welwyn

- Wickmann

- Winbond

- Xilinx

- Yageo

- Zetex Semiconductors

- ZJPT / Maojwei

News

TDK introduces tube magazines for various series of ring core chokes for automatic pick and place

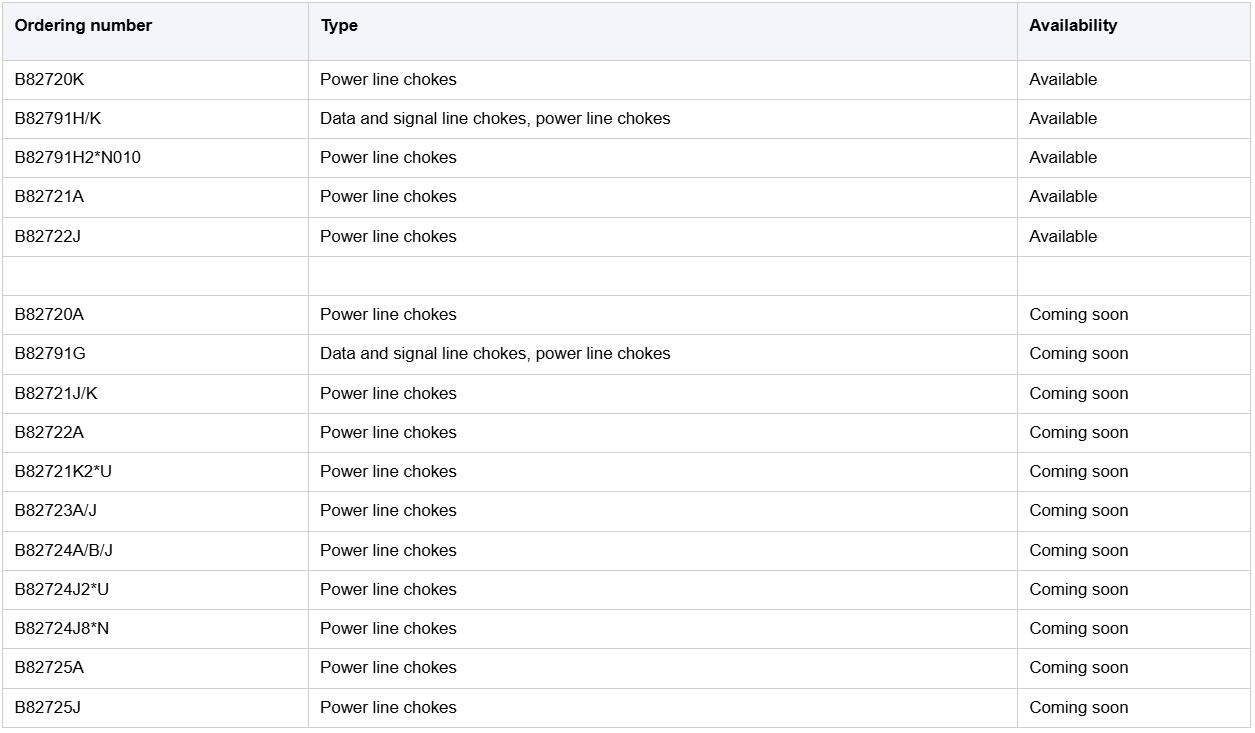

2024-08-20 | Return TDK Corporation introduces tube magazines for several ring core chokes series as an alternative packaging to the blister tray in a cardboard box. Tube magazines provide a reliable, efficient, and automated way to handle and supply components in a production line, which is crucial for maintaining high throughput and quality in manufacturing processes. The table below shows which component series these are, and which are already available or coming soon.

TDK Corporation introduces tube magazines for several ring core chokes series as an alternative packaging to the blister tray in a cardboard box. Tube magazines provide a reliable, efficient, and automated way to handle and supply components in a production line, which is crucial for maintaining high throughput and quality in manufacturing processes. The table below shows which component series these are, and which are already available or coming soon.Components within a tube magazine are typically aligned in a consistent orientation. This makes it easier for the automated pick-and-place machinery to identify and handle each component correctly, reducing the likelihood of errors during placement. Tube magazines can be easily integrated with automated feeders which can push components out of the tube one at a time, ensuring a steady supply of parts to the pick-and-place machine without manual intervention. Keeping components in a tube magazine protects them from physical damage that could occur during manual handling. Many automated pick-and-place machines are designed to work seamlessly with tube magazines, ensuring smooth and efficient operation. The standardized design of tube magazines allows for quick setup and changeover between different production runs.

Features & Applications

Main applications

- Suppression of common-mode interferences

- Switch-mode power supplies

- Power inverters

Main features and benefits

- Efficient component storage

- Consistent orientation of the components

- Automated feeding for pick-and-place machinery

- Reduced handling damage

- Minimized downtimes and changeover times in the production line

Key Data

Source:https://www.tdk.com/