Manufacturers

- Abracon

- Adam Tech

- Aerospace, Defense & Marine

- Agastat

- AIC

- AKM Semiconductor

- Alcoswitch

- Allegro

- Alps Electric

- Altera

- AMI Semiconductor

- AMP

- ams

- Analog Devices (ADI)

- Aptina Imaging

- Atmel

- Avago / Broadcom

- AVX

- Axicom

- Bccomponents

- Beyschlag

- BI Technologies

- Bourns Inc.

- Bowei Integrated Circuits

- Bridgelux

- Buchanan

- California Micro Devices

- Catalyst Semiconductor

- CGS

- Cirrus Logic

- Citizen Electronics

- CML Microcircuits

- Coiltronics

- Cooper Bussmann

- Corcom

- Core Logic

- Cree

- CSR PLC

- CTS

- Cypress Semiconductor

- Dale

- Data Image

- Deutsch

- Diodes Incorporated

- DOMINANT Opto Technologies

- E-T-A

- Eaton

- ECS

- Edison Opto

- Elcon

- EPCOS

- Epistar

- Epson

- Everlight Electronics

- Exar

- Fairchild Semiconductor

- FCI

- Freescale Semiconductor

- Fremont Micro Devices (FMD)

- Fujitsu Semiconductor

- Fulltech Electric

- General Semiconductor

- Harvatek

- Holsworthy

- Hsuan Mao Technology

- IDT

- Infineon Technologies

- Innolux

- International Rectifier (IR)

- Intersil

- IRC

- ISSI

- IXYS-IC

- Jing Cheng Electronical

- JL World

- Johanson Dielectrics

- Johanson Technology

- JRC / NJR

- JST

- KEC

- Kilovac

- Kingbright

- Kyocera Industrial Ceramics

- LEDiL

- Linear Technology / ADI

- Lite-On Technology

- Littelfuse

- Lumex

- Lumileds

- Luminary Micro

- Luminus Devices

- Macronix

- Maojwei / ZJPT

- Maxim Integrated

- MCC

- Mean Well Enterprises

- Microchip Technology

- Micron

- Microsemi

- Mini-Circuits

- Molex

- Murata Manufacturing

- Murata Power Solutions

- MWT

- National Semiconductor

- Nichicon

- Nippon Chemi-Con

- NJR / JRC

- NVE

- NXP Semiconductors

- OEG

- Omnivision

- ON Semiconductor

- Optek Technology

- Optrex

- OSRAM Opto Semiconductors

- OTAX

- Panasonic

- Peregrine(pSemi)

- Potter & Brumfield

- Power Integrations

- PowerStor

- Preci-Dip

- Prewell

- Products Unlimited

- Pulse Electronics

- PulseCore Semiconductor

- Qorvo

- Raychem

- Renesas Electronics

- RFMD

- Richtek Technology

- ROHM Semiconductor

- Rubycon

- Samsung Electro-Mechanics

- Samsung Semiconductor

- Schaffner

- Schrack

- Seiko Instruments, Inc. (SII)

- Semtech

- Sensata

- Seoul Semiconductor

- Sfernice

- Sharp Display

- Sharp Microelectronics

- Silicon Labs

- Siliconix

- Skyworks Solutions

- SoniCrest / JL World

- Spansion

- Sprague

- Stanley Electric

- STMicroelectronics

- Sunny Electronics

- Susumu (SSM)

- Taimag

- Taiyo Yuden

- TDK

- TDK-Lambda

- TE Connectivity

- Teccor

- Texas Instruments (TI)

- Thin Film

- Tianma Micro-electronics

- TOCOS

- TOKO

- Toshiba Electronic Components

- TT Electronics

- Tusonix

- TXC

- Tyntek

- Vishay

- Vishay Precision Group

- Vitramon

- Walsin Technology

- Weidmuller

- Welwyn

- Wickmann

- Winbond

- Xilinx

- Yageo

- Zetex Semiconductors

- ZJPT / Maojwei

新闻中心

NJR has begun to provide the samples of Dual/Quad Single-supply

2021-01-25 | 返回While inheriting the generality of the industry standard operational amplifiers NJM2904 / NJM2902, EMI immunity has been greatly improved.

In all automotive ECU designs from body system to power train, they contribute to significant improvement of design quality such as risk reduction of design rework, reduction of EMC design man-hours, risk reduction of replacement.

※1 Researched by NJR in January, 2021

※2 ECU: Electronic Control Unit

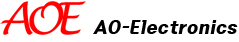

『Achieve industry-leading EMI immunity』

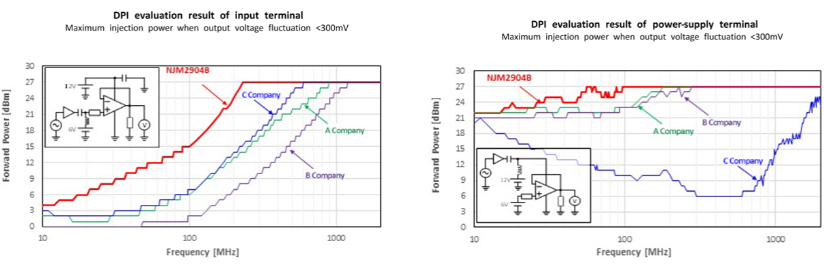

●Testing result by DPI testing according to international standards IEC 62132-4, ED-5008

The result shows that when the output voltage fluctuation is less than 300mV, the maximum injection power is higher, the EMI immunity is stronger.

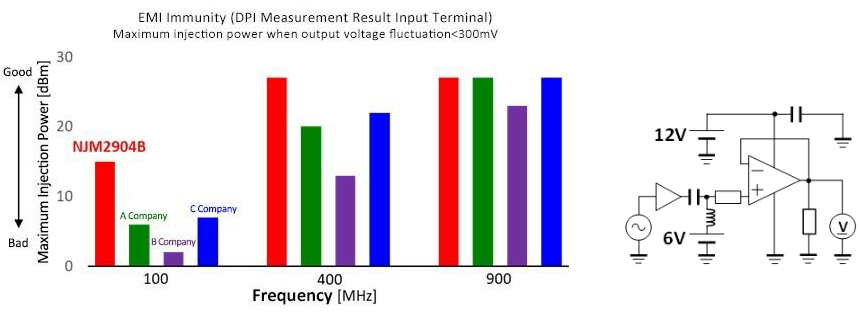

Development Background

When the operational amplifier used in automotive ECU is interfered by the external electromagnetic noises (EMI) beyond the operating frequency, the output voltage will fluctuate, and the ECU will be malfunction.

The noise immunity are generally evaluated in the final stage of vehicle development. If a problem is discovered, the design of ECU pattern and the selection of mounted parts return from the analysis to the countermeasures. It will affect the design man-hours.

The multi-function of vehicle increases the number of installed ECUs. However, the increase of smart phones and electronic devices with communication functions has made electromagnetic interference become very serious. Therefore, there are stronger demands for operational amplifiers with high EMI immunity.

Features

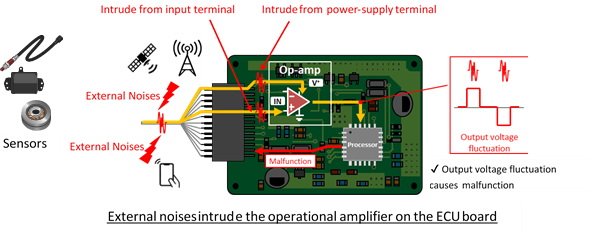

1. In addition to the input terminal, the EMI immunity of the power-supply terminal has also been enhanced

The EMI interference of operational amplifier generally intrudes from the input terminal with weak EMI immunity, so the EMI immunity countermeasures of most products have been taken only for the input terminals. However, considering the noises superimposed on the wire harness intrude from the power supply terminal of the amplifier, the interference countermeasure is not complete.

NJR has taken optimal EMI countermeasures for each stage based on the exhaustive analysis of the EMI noise intrusion path to each stage circuit of the operational amplifier, the effect on the circuit operation, and the mechanism of the malfunction. Therefore, not only the input terminal, the EMI immunity of the power-supply terminal has also been successfully improved to the industry-leading level.

Since it is a countermeasure for IC internal circuits, it is hard to be affected by the chip layout and the assembly conditions, provides stable EMI immunity, and reduces the risk of design rework after the noise evaluation.

2. Achieve industry-leading EMI immunity as a single component by the noise evaluation based on IEC 62132-4

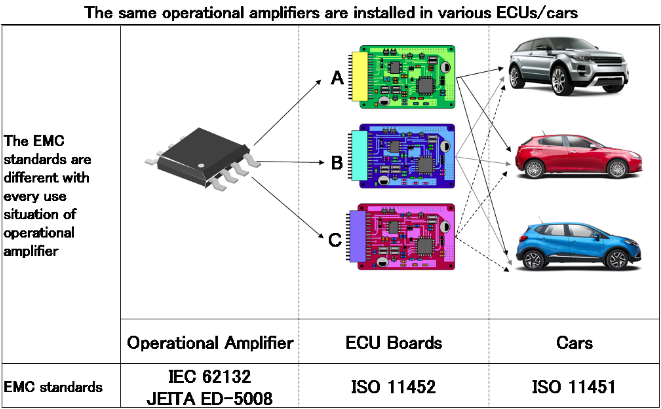

Operational amplifiers are used for various applications, and the same operational amplifiers are installed in various electrical and electronic devices. Since the required EMC standards are different with every situation, it is very important to compare and evaluate the EMI immunity of a single operational amplifier properly.

The NJM2904B / NJM2902B have been compared / evaluated based on the international standard IEC 62132-4*3 and JEITA standard ED-5008*4, and confirmed that they are the industry-leading level. So you can use them with confidence from new design to consideration of replacement.

【DPI evaluation results based on IEC 62132-4, ED-5008】

Both the input terminal and the power-supply terminal have achieved the industry-leading EMI immunity. The power-supply terminal is ensured high EMI immunity without bypass capacitors. In this evaluation, the upper limit of injection power is 27 dBm.

※3 IEC 62132-4

It is one of the IEC 62132 series that measure the EMC (immunity) of semiconductors. DPI (Direct Power Injection) testing according to IEC 62132-4 is a test that evaluates immunity performance by injecting power into the IC terminal with capacitive coupling and measure the limit power when the IC operates normally.

※4 ED-5008

It is a JEITA standard, EMC Performance equivalence test of semiconductor. It is a standard for evaluating the EMC performance differences of semiconductors, and the evaluation method conforms to IEC 62132-4.

Appearance

Characteristics

> NJM2904/NJM2902 Forward compatibility

・Wide operating voltage : +3V to 36V

・Low current consumption : typ.0.7mA

・Low input offset voltage : typ.2mV , max.4mV

> AEC-Q100(Grade1) : plan to test based on the 2022 standards

> Single-supply, ground sensing

> Package : MSOP8/SSOP14

Applications

> Automotive ECUs

> Voltage sense amplifiers, current sense amplifiers

> various sense amplifiers

> various filters, wave shaping circuits

Source:http://www.njr.com/